Abbreviation :PP, a thermoplastic resin prepared by polymerization of propylene. According to the methyl group position is divided into three kinds: isotaetic PolyProlene, atactic PolyPropylene and syndiotatic PolyPropylene.

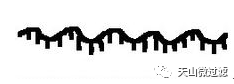

Isotactic structure

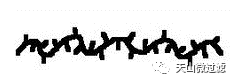

Syndiotactic structure

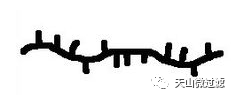

Disordered structure

Features:

1. Physical properties: PP (polypropylene) is non-toxic, odorless, tasteless milky white high crystalline polymer, density: 0.90-0.91g/cm3, especially stable to water, 24 hours in the water absorption rate of 0.01%, molecular weight between 8-150,000. Good molding, but the shrinkage rate is large, manufacturing thick wall products easy to sag. Product surface gloss is good, easy to color.

2. Mechanical properties: PP (polypropylene) has high crystallinity, regular structure, good mechanical properties, its strength and hardness, elasticity are good, but at room temperature and low temperature impact strength is poor, when the molecular weight increases, impact strength also increases, but the molding processing performance becomes worse. The most outstanding property of PP (polypropylene) is its resistance to bending fatigue. The coefficient of dry friction is similar to nylon, but not as good as nylon under lubricating oil.

3. Thermal performance: PP (polypropylene) has good heat resistance, melting point in 164-170℃, made of products can be sterilized at temperatures above 100℃; In the case of no external force 150℃ is not deformed. The embrittlement temperature was -35 ℃.

4 chemical stability: PP (polypropylene) chemical stability is very good, in addition to be concentrated sulfuric acid, concentrated nitric acid erosion, on other various chemical reagents are relatively stable, but low molecular weight aliphatic hydrocarbon, chlorinated hydrocarbon can make PP (polypropylene) softening and swelling.

1. Electrical properties: PP (polypropylene) high frequency insulation performance is excellent, because it almost does not absorb water, so absolutely

Edge performance is not affected by humidity. PP (polypropylene) has a high dielectric coefficient, as the temperature rises, can be used to make heated electrical insulation products, its breakdown voltage is also very high. PP (polypropylene) voltage resistance, arc resistance is good, but high electrostatic degree, easy to aging contact with cop.

Advantages and disadvantages of polypropylene material:

Advantages:

1, the relative density is small, only 0.89-0.91, is one of the lightest plastic varieties.

2, good mechanical properties, in addition to impact resistance, other mechanical properties are better than polyethylene, forming processing performance is good.

3, with high heat resistance, continuous use temperature up to 110-120℃.

4, good chemical performance, almost no water absorption, and the vast majority of chemicals do not react.

5, pure texture, no toxicity.

6, good electrical insulation.

7. The transparency of polypropylene products is better than that of high-density polyethylene products.

Disadvantages:

1, the product cold resistance is poor, low temperature impact strength is low.

2, the product is vulnerable to light, heat and oxygen in use and aging.

3, coloring is not good.

4, easy to burn.

5, toughness is not good, high electrostatic, dyeing, printing and adhesion is poor.

Post time: Sep-06-2022